Understanding and optimizing your cost to serve (CTS) is crucial to maintaining healthy profit margins in business. Cost to serve refers to the total cost incurred by a company to provide products or services to its customers. The costs to acquire the customer are not included in this calculation; they are only the cost to fulfill the customer's purchase. Therefore, high CTS can significantly erode profitability regardless of how well your customer acquisition cost (CAC) is optimized. Conversely, reducing CTS can boost margins and provide a competitive advantage. This article will delve into what cost to serve entails, how to calculate it, why reducing it matters, and proven CTS optimization strategies for your organization.

What is Cost to Serve (CTS)?

How to Calculate Cost to Serve

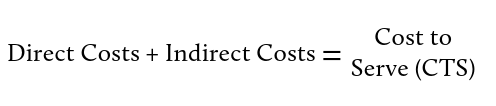

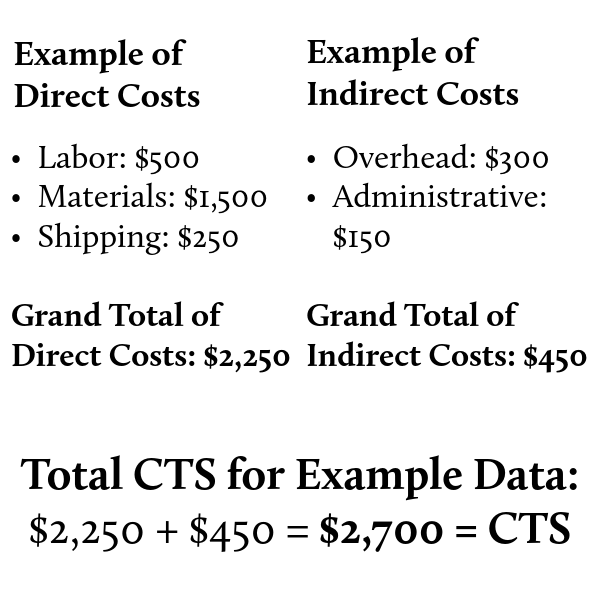

Calculating cost to serve involves several steps:

1. Identify all relevant cost elements, including direct costs (e.g., labor, materials, shipping) and indirect costs (e.g. overhead, warehousing, administrative)

2. Allocate costs accurately to specific customers, products, or channels based on the resources consumed

3. Determine the unit of measure (e.g., per order, per item, per pound)

4. Calculate total CTS by adding up all allocated costs

Some costs are more challenging to categorize. An example would be software. Each business uses software differently, so some will include it in their direct cost calculations, while some other software at the same company could be considered indirect costs. Here's a good way of thinking about which category to put each software into:

Software is considered a direct cost when:

- It is specialized software that supports a project's specific technical aims; it should not be general-purpose software.

- The cost can be easily traced back to the development of a specific product or service. For example, if a team uses software specifically to make a product, it is a direct cost.

- It costs less than $100,000. Software costing less than $100,000 is not considered capital equipment and can be a direct cost.

On the other hand, software is considered an indirect cost when:

- It is general-purpose software like word processing and spreadsheet programs. These costs are usually classified as indirect costs under office supplies.

- The software cost cannot be directly traced to a specific product. For example, if you pay for software to run a facility that hosts a machine, which is then used to make a product, the software cost is indirect because it does not directly contribute to the end product.

- It is a general business expense that keeps the company operating but doesn't directly produce goods or services, such as accounting software.

Therefore, specialized software that can be directly attributed to a specific project or product is usually a direct cost, while general software that supports overall business operations is typically an indirect cost. The key is whether the software cost can be clearly traced to the final product or service.

Example Cost to Serve (CTS) Calculations

For example, let's say a company has the following monthly costs for serving Customer A:

Direct Costs

- Labor: $500

- Materials: $1,500

- Shipping: $250

Grand Total of Direct Costs: $2,250

Indirect Costs

- Overhead allocation: $300

- Administrative costs: $150

Grand Total of Indirect Costs: $450

The total CTS for Customer A would be:

$2,250 + $450 = $2,700

Accurately allocating costs is crucial for getting an accurate picture of profitability by customer or product. Many companies use activity-based costing to assign indirect costs based on the activities and resources each customer or product consumes. Calculating exact numbers like this can be difficult, but it is possible if you track resource allocation through your project management systems. Our organization has helped companies with both small and large teams establish cross-department project management systems to gather this data. If your organization wants a better understanding of your cost to serve customers, we can help establish detailed resource tracking to support data gathering and improved resource allocation.

Why Reducing Cost to Serve Matters

1. Boosting profitability

2. Enabling data-driven decision making

3. Improving customer relationships

4. Enhancing competitiveness

5. Fueling growth and innovation

Strategies to Reduce Cost to Serve

Reducing cost to serve requires a multifaceted approach unique to each business and industry. We've gathered some of the most common, though some strategies may not apply directly to your business. If you're looking to improve your cost to serve, our operations consulting services have helped reduce costs through optimization and automation.

1. Improve Supply Chain Efficiency or Process Efficiency with Workload Balancing

Whether you work directly in supply chain or not, it's likely impacting your product costs. Therefore, one of the most impactful ways to reduce cost to serve is by streamlining supply chain processes from end-to-end. Analyze each step of the supply chain to identify bottlenecks, redundancies, and opportunities for improvement. For service-based businesses, consider the efficiency of fulfilling services as a form of supply chain. Regarding cost, a vendor that is inefficient with their time to complete work costs you more and delays deliverables for your end customer. Some ways to improve supply chain efficiency include:

Optimize inventory levels & Resources: Carrying excess inventory ties up working capital and increases holding costs. By using advanced demand forecasting techniques and collaborating closely with suppliers, companies can maintain optimal inventory levels that balance customer service with cost efficiency. For service-based companies, this means tracking and balancing your internal team workloads and having a variety of contractors and vendors to help handle bottlenecks or spikes in demand.

Streamline warehousing and distribution or reduce unnecessary communications and confusion: Inefficient warehouse layouts, manual processes, and suboptimal transportation routing can add significant costs. If you're in a business that includes warehousing, implementing lean warehousing principles, automating key processes, and optimizing distribution networks can dramatically reduce operating expenses. For service-based businesses, the equivalent waste is most often found through increased communication due to a need for more transparent processes and standard operating procedures (SOPs).

Similar to any warehouse, proper setup, training, and information on what to do under the most common conditions of work is vital to a smooth delivery of services. If teams regularly have to communicate, set up meetings with too many individuals, and argue about the way to solve a problem, you should be working to improve your training and SOPs so your teams can focus on their primary tasks rather than creating stoppages through unnecessary communication between steps just for clarity.

Leverage supply chain and project management visibility tools: Lack of real-time visibility into inventory levels, shipments, and supplier performance makes it difficult to identify issues and opportunities. Investing in supply chain visibility platforms that provide end-to-end transparency enables faster decision-making and improved collaboration. Similarly, project management systems were built not only to assign your team their tasks but to gather the data necessary to improve your service delivery. If you have a PM system but aren't regularly gathering and analyzing the data to break down bottlenecks, improve processes, and learn where the team needs improved training, you aren't using the entire benefit of the system.

2. Optimize Inventory Management & Skills-Based Hiring

Inventory management has a direct impact on cost to serve, as it affects product availability, working capital requirements, and warehousing expenses. Optimizing inventory can yield significant cost savings. For service-based businesses, we consider the correlation to be with worker's knowledge. So hiring for the right skills to deliver on your services, upskilling and reskilling to improve existing teams, and focusing on the potential of existing and new talent for the organization is key.

Product Based Businesses

Implement demand-driven inventory planning: Traditional inventory planning based on historical sales can lead to stockouts or excess inventory. Shifting to a demand-driven approach incorporating real-time sales data, market trends, and customer insights enables leaner, more responsive inventory management. Modern technology can help track and forecast demand, so your team handles these changes with ease.

Differentiate inventory by value and velocity: Not all products should be managed the same way. Segmenting inventory based on metrics like profitability, sales volume, and demand variability allows for tailored strategies. For example, using a just-in-time approach for slower-moving items and maintaining higher stock levels for top sellers are strategies you may consider.

Reduce dead stock and obsolescence: Excess inventory that isn't selling incurs high carrying costs and risk of obsolescence. Implementing regular reviews to identify and liquidate dead stock, as well as improving demand forecasting accuracy, can minimize this costly issue. Just remember that intentional waste is never something we recommend businesses engage in. We've seen businesses destroy and throw away dead stock to take the full write-off. Even if that's legal in your country, it's unthinkable to us considering the item's usefulness. Make sure you've got contingency plans as part of your write-off process so you can efficiently sell them to a liquidator or donate them rather than destroy them. You may even capture more write-off value that way.

Service Based Businesses

While still relevant for product-based businesses, hiring practices for service based businesses are a good correlary when compared with product inventory management. Ensuring your team has the proper knowledge at the right time means a more efficient and effective use of the team members for service delivery, further reducing cost to serve. Whether you focus on new hires or upskilling team members you have already hired, the proper practices are one of the lowest-cost ways to deliver services at a reduced cost to serve. Training programs and better hiring practices are certainly more affordable than the estimated 150-200% of salary costs it takes to replace an employee instead.

Hiring for the right skills reduces the cost of a bad hire:

Skills-based hiring focuses on the specific abilities needed for open roles, helping reduce cost to serve. By clearly defining the skills required and screening candidates based on their competencies rather than just degrees or years of experience, service businesses can avoid the high cost of a bad hire who lacks the critical skills needed to perform well for the work at hand.

Upskilling and reskilling maximize the value of human capital: Just as product businesses aim to maximize the usage and value of physical inventory, service businesses need to get the most out of their human capital. Providing training to upskill and reskill employees in high-demand areas allows a company to deploy talent more flexibly to meet shifting needs without always hiring externally. This reduces cost-to-serve by improving utilization of the skills inventory.

Hiring for potential expands the talent pool: Skills-based hiring also emphasizes evaluating candidates' potential to learn new skills rather than focusing only on existing skills and experience. This opens up a broader, more diverse talent pool, allowing service businesses to find high-potential talent that traditional degree requirements may have screened out. Drawing from a larger pool can reduce hiring costs.

Targeted training prevents skills shortages: Proactively analyzing skills gaps and providing training in those areas helps service businesses avoid expensive skills shortages that could impact the quality and efficiency of service delivery. Maintaining a skills inventory through training controls costs by reducing the need for last-minute hiring or high-priced contractors to fill gaps.

3. Streamline Order Fulfillment and Optimize Workflows

Order fulfillment is a key driver of cost to serve, impacting labor requirements, shipping expenses, and customer satisfaction. Streamlining these processes can significantly reduce costs while improving service levels. For service-based businesses, this is all about process optimization and automation.

Optimize picking and packing and establish standardized processes: Inefficient picking routes, manual processes, and poor layout can slow down order processing and increase labor costs. Leveraging technologies like voice-directed picking, pick-to-light systems, and automated guided vehicles can boost productivity and accuracy. For service-based businesses, this is like running a project that has to be custom-built every time, even if it's a standard workflow. Make sure you have templates built out, and team members trained on all the standard processes necessary to deliver the service. Systems like that can also help you analyze those processes to see where to improve and optimize over time.

Automate order processing and standard role functions: Manual order entry and processing is time-consuming and error-prone. Implementing EDI, API integrations, and automated order processing workflows can reduce manual intervention, speed up cycle times, and cut costs. Similarly, automation for service-based businesses has resulted in significant efficiency gains for those teams. In many ways, automation in the office setting is outpacing automating physical processes, primarily because of the outputs of artificial intelligence and machine learning technologies. Ensure your team knows how to work with and integrate automation and AI into their daily work to significantly reduce cost to serve.

Implement dynamic slotting: Storing products based on sales velocity and pick frequency can minimize travel time and improve picking efficiency. Regularly reviewing and adjusting slotting based on changing demand patterns keeps fulfillment operations optimized. For service-based teams, a correlated efficiency is having a skills-based, cross-functional rapid response team that can step in to help balance workloads when project requirements align, increasing demand for resources above the fixed resource capability. Those team members should have other nonpriority jobs or work that can be delayed, which they would typically be doing in between resource "fires."

4. Implement Automation and Technology

As mentioned in a variety of the specific solutions above, Automation and advanced technologies are powerful tools for reducing cost to serve. While they require upfront investment, the long-term ROI can be substantial in terms of efficiency gains, error reduction, and scalability.

Utilize warehouse management systems (WMS) and Project Management Systems (PMS): A robust WMS is the backbone of efficient warehouse operations. It optimizes processes like receiving, putaway, picking, and shipping while providing real-time inventory visibility. Cloud-based WMS solutions offer scalability and rapid implementation. Project management systems provide similar functionality and benefits for service-based companies looking to reduce their cost to serve.

Implement robotic automation and process automation: Automated storage and retrieval systems (AS/RS), autonomous mobile robots (AMRs), and robotic picking arms can significantly reduce labor costs and increase throughput in warehousing and fulfillment. As the technology matures, the ROI of automation is becoming increasingly attractive. Likewise, process automation is vital for the office staff to reduce standardized and repeated administrative work. Integrating platforms is a great way to ensure that basic data work is a thing of the past and errors are reduced to near zero.

Leverage artificial intelligence and machine learning: AI and ML can optimize complex supply chain planning and execution processes. For example, using ML algorithms for demand forecasting, predictive maintenance, and dynamic route optimization can yield significant cost savings and service improvements. Now, with generative AI, various creative workflows can also be streamlined. However, as this technology is so new, it's essential to monitor the regulations in the different regions that have power over your organization to ensure alignment and avoid unnecessary fines.

5. Analyze Profitability by Customer and Product

Not all customers and products are equally profitable. For both product—and service-based businesses, gaining granular insights into profitability enables targeted strategies to optimize cost to serve.

Implement activity-based costing: Traditional costing methods often fail to capture the true cost of serving specific customers or fulfilling certain products. Activity-based costing allocates expenses based on the actual resources consumed, providing a clearer picture of profitability.

Identify and address unprofitable relationships: Customers or products with high cost to serve relative to revenue may be draining profits. Analyzing profitability data can uncover opportunities to adjust pricing, minimum order quantities or service levels to better align costs with value.

Develop differentiated service levels: Providing the same level of service to all customers is often inefficient. Segmenting customers based on profitability and strategic importance allows for tiered service levels that optimize cost to serve while meeting key customer requirements.

6. Adjust Service Levels Based on Customer Value

Aligning service levels with customer profitability ensures that high-value customers receive the attention and resources they require while lower-value customers are served cost-effectively.

Segment customers by profitability: Analyze customer profitability data to group customers into tiers based on metrics like revenue, cost to serve, and strategic value. This segmentation provides a foundation for differentiated service strategies.

Tailor service levels to customer segments: Define service level agreements (SLAs) for each customer tier that balance service expectations with cost efficiency. For example, top-tier customers may receive priority order processing, expedited shipping, and dedicated account management, while lower-tier have more standardized service.

Monitor and adjust service levels regularly: Customer needs and profitability can change over time. Regularly reviewing customer segmentation and service level performance ensures that resource allocation remains optimized.

7. Renegotiate Supplier Contracts or find new Vendors

Supplier relationships have a significant impact on cost to serve. Regularly reviewing and renegotiating contracts can uncover opportunities for cost savings and performance improvements. Sometimes, it may just be time to move on to another vendor if they can offer the same products or services at a more affordable cost.

Conduct regular supplier performance reviews: Assess suppliers based on metrics like on-time delivery, quality, responsiveness, and total cost. Identify top performers as well as those who may be falling short.

Leverage volume and consolidation: Analyze total spend across suppliers to identify volume discounts or consolidation opportunities. Negotiating better terms based on aggregate spend can yield significant savings.

Explore value-added services: Some suppliers may offer additional services like vendor-managed inventory, consignment stock, or direct-to-customer shipping. Leveraging these services can reduce internal costs and improve efficiency.

8. Foster a continuous improvement culture

No matter what business you are in, reducing cost to serve is an ongoing journey, not a one-time project. Building a culture of continuous improvement ensures that optimization efforts are sustained and evolve over time.

Implement lean principles: Lean methodologies like Six Sigma and Kaizen focus on eliminating waste, reducing variability, and continuously improving processes. Training employees in lean principles and empowering them to identify and implement improvements can drive significant cost savings.

Establish cross-functional collaboration: Breaking down silos between departments like sales, operations, and finance is critical for aligning goals and driving holistic improvements. Establishing cross-functional teams and regular communication cadences fosters collaboration and innovation.

Measure, monitor, and adjust: Defining clear KPIs, setting targets, and regularly monitoring performance is essential for driving continuous improvement. Celebrating successes and openly discussing challenges creates a culture of transparency and accountability.

Reducing cost to serve requires a strategic, data-driven approach that addresses inefficiencies and waste throughout the supply chain. Companies can optimize operations, improve profitability, and build a sustainable competitive advantage by implementing these proven strategies. However, it's important to remember that cost reduction should never come at the expense of customer satisfaction or product quality.

The most successful companies strike a balance between efficiency and effectiveness, continuously adapting their strategies to meet evolving customer needs and market conditions. With the right mindset, tools, and partnerships, any company can start the journey towards a leaner, more profitable supply chain.